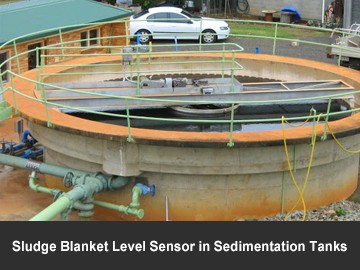

Sludge Blanket Level Sensor in Sedimentation Tanks

According to the global sewage discharge data collection in 2020, the number of sludge blanket level sensors used in sedimentation tanks has exceeded 8 million. Purification of drinking water from sewage can not only reuse water resources, but also raise our awareness of the importance of water resources. Thus it can be seen that the position of sludge blanket level sensor is pivotal.

There are many kinds of sludge blanket level sensors used in sedimentation tanks on the market. Therefore, most of people choose sensors based on their subjective consciousness. There are a few engineers and municipal workers who believe that the price of the product determines the quality of the product, and the more expensive the sensor, the more secure we are. In fact, we need to select the appropriate level sensor from the shape, range and composition of the sedimentation tank. Before measurement, we need to know that the sedimentation tank can be divided into horizontal sedimentation tank and vertical sedimentation tank according to the direction of water flow. Excessively fast water flow speed will impact the sensor probe, thus affecting the measurement accuracy. The vertical sedimentation tank has a large range, and the sediment at the bottom of the tank cannot be estimated, so we need to consider all aspects.

How did I use sludge blanket level sensor in sedimentation tanks?

Generally, the sludge blanket level sensor is divided into Submersible Sewage Water Level Transducer and Anti Clogging Slurry Level Sensor. The first sensor is mainly used for measuring the level of ordinary sewage or waste water, and the second sensor is mainly used for sewage containing weeds and stones. The measurement methods of the two level sensors are similar. So the way they are used is that we should know the approximate depth of the sedimentation tank and whether the sewage contains other impurities before we measure it. Once confirmed, the sensor is connected to the USB485 converter, and the converter is connected to the power supply, and the power switch is connected to the notebook or digital display instrument. At this time, we can clearly know the liquid level changes of the sludge layer and the water layer. In my opinion, this measurement method not only saves the purchase cost, but also is easy to operate and almost maintenance-free, which are advantages that non-contact sensors cannot achieve.