Never install a submersible water level sensor? Just follow the steps below!

The submersible water level sensor is widely used in water level and liquid level measurement and control in petroleum, chemical, power plant, urban water supply and drainage, hydrological exploration and other fields. The transmitter is simple to operate and easy to install. However, some customers also encounter some difficulties during the installation process, so the author has organized the site installation steps of the level sensor as follows:

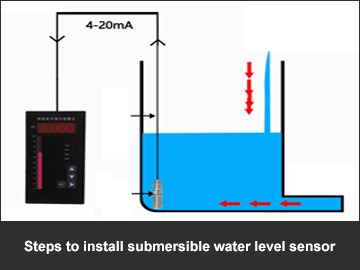

- 1.Submersible water level sensor installation---according to the site conditions, slowly put the liquid level sensor into the measured medium and placed in a suitable position to ensure that the diaphragm is not squeezed and the sensor is well sealed.

- 2. Wiring and energizing---connected the senors and the digital display controller correctly, make sure there is no problem in signal output and reception.

- 3.Debugging---The zero calibration and parameter setting of the liquid level transmitter to ensure that the digital display meter and the instrument display are synchronized and consistent. The upper and lower alarm values are set according to site requirements and connected to the PLC.

- 4. Actual calibration---Filled with the required medium in the on-site storage tank , the value displayed by the meter and the digital display is in line with the actual situation, and be sure there is no leakage at the meter installation.

When installing submersible water level sensor, we need to pay attention to the following points to ensure that the sensor can accurately and effectively measure. First of all, because the bottom of the tank is prone to deposit sludge, oil residues, etc., it is recommended to leave the measuring probe at a certain height from the bottom of the tank (cabin) to prevent sundries from blocking the probe. Secondly, when the medium fluctuates greatly and the air guiding cable is very long, the probe should be fixed with a sleeve to prevent the probe from swinging and affecting the measurement accuracy. In addition, when the transmitter is installed on the side, the bend radius of the air guide cable should be greater than 10 cm to avoid damage to the air guide cable due to excessive bending. Finally, the ground terminal of the submerged liquid level transmitter should be reliably grounded, and the power shield wire should be connected to it.

we can easily fix the installation of the submersible water level sensor as long as the above steps are combined with the precautions. We can effectively protect our sensors and achieve better results.