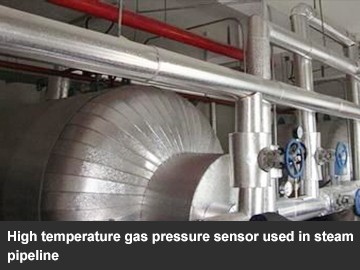

High temperature gas pressure sensor used in steam pipeline

High temperature gas pressure sensor has become the first choice for steam pipeline pressure monitoring is mainly because the temperature in the steam pipeline is generally relatively high, and the start and stop of the valve will also cause the pressure in the pipeline to fluctuate. In order to effectively guarantee the safety and reliability in production process, high-temperature pressure sensors with high accuracy and stability are mostly used.

High temperature gas pressure sensor uses high-quality imported sputtered film pressure sensor diaphragm and sapphire pressure sensor. With high-reliability amplification circuit and precision temperature compensation, the pressure of the measured medium is converted into various forms of standard electrical signals, which can be applied in condition that medium temperatures is up to 200 ° C. The maxium pressure measurement range can be customized up to 2000Bar, which can perfectly meet the high temperature and high pressure monitoring requirements in pipeline measurement. The product uses stainless steel material and special protective structure. The circuit is designed with a series of protection methods such as anti-lightning, anti-interference, anti-overvoltage, and overcurrent, which improves the ability of sealing and anti-corrosion and resisting harsh working environment. When measuring the gas pressure in the steam pipeline, we only need to open the pressure inlet at the top of the process pipeline, and install the high temperature pressure sensor correspondingly in the upper part of the process pipeline, so that the accumulated liquid can be easily injected into the process pipeline, and then connect the cable and tighten the nut to monitor the pressure data of the solicited pipeline.

Although high temperature gas pressure sensor is more suitable for pressure measurement in a high-temperature and high-pressure measurement environment such as pipeline steam, it is still necessary to connect a condenser such as a buffer tube (coil) when measuring steam or other high-temperature media. The operating temperature of the transmitter should not be exceeded to avoid damage to the sensor.