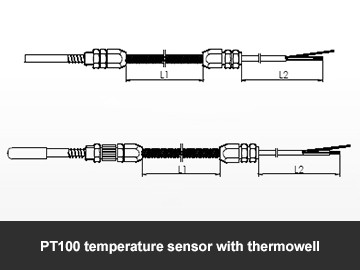

PT100 temperature sensor with thermowell

PT100 temperature sensor with thermowell refers to the protective sleeve placed outside the temperature measuring element or pre-installed on the PT100 thermal resistance temperature sensor to resist the pressure and corrosion of the measured medium.

PT100 temperature sensor with thermowell can be used in high pressure and high flow rate applications. Of course, the installation of the casing needs to be customized according to different pressure occasions. In the selection of casing, it is necessary to pay attention to the following key technical parameters:

1. Nominal pressure: generally refers to the static external pressure that the protective tube can withstand at normal temperature without rupture. The allowable working pressure is not only related to the material, diameter and wall thickness of thermowell, but also to its structural form and type of installation method.

2. Water pressure test: When there is a requirement for the pressure resistance and leakage inspection of the thermowell, the thermowell tube must be tested. The test pressure is 15 times the pressure rating of the protective tube.

3. Medium flow rate: The thermal installation sleeve is used in a medium with a flow rate not exceeding 80m / s.

The mechanical properties, corrosion resistance, and oxidation resistance of the PT100 temperature sensor with thermowell are determined by the material of the sleeve and the temperature range that the customer needs to measure. Therefore, when selecting an industrial casing, we need to contact technical personnel to decide which casing to choose based on a series of parameters such as model, insertion depth, casing material and so on. The casing cannot be chosen at will to avoid the situation where the use effect is not ideal.