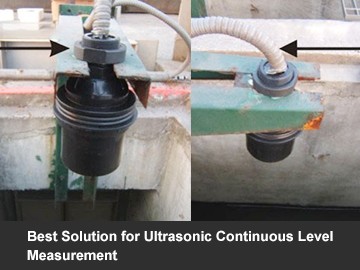

Best Solution for Ultrasonic Continuous Level Measurement

The method of continuously measuring the liquid level using an ultrasonic continuous level measurement is recognized by the user. However, during the measurement process, some ultrasonic level sensors could not meet the standard of continuous measurement, which caused the measurement work to be stopped. As you know, the ultrasonic level transducer completely solves the problems of winding, leakage, contact medium, and expensive maintenance caused by pressure sensors, capacitive floats, etc. The ultrasonic level gauge does not need to touch the industrial medium. It can meet the level measurement requirements in most closed or open containers.

In the actual measurement environment, the following problems need to be solved. Through these practical problems, we can find the best solution for ultrasonic continuous level measurement. Fault phenomenon: The ultrasonic liquid level sensor data beats irregularly.

Reason: There will be many motors, inverts and electric welding in the industrial field that will affect the measurement of the ultrasonic level gauge. The electromagnetic interference will exceed the echo signal received by the probe.

The ultrasonic ultrasonic continuous level measurement must be grounded. After grounding, some interference on the circuit board will run off through the ground wire. This grounding is to be grounded separately. It cannot be shared with other equipment. The power supply cannot be the same as the inverted and the motor. The power supply cannot be directly led from the power system power supply. The installation location should be far away from the inverted, variable frequency motor, and high-power electric equipment. If it cannot be kept away, it is necessary to install a metal instrument box outside the liquid level gauge to isolate the shield. The box should also be grounded.