How to install submersible diesel tank level sensor

The oil storage tank is an important device for storing oil products. The accurate measurement of the oil tank liquid level has a great impact on the inventory management and economic operation of the production plant. Therefore, the use of submersible diesel tank level sensor for oil tank level measurement and monitoring has become an important means for enterprises to grasp the production status and ensure production safety.

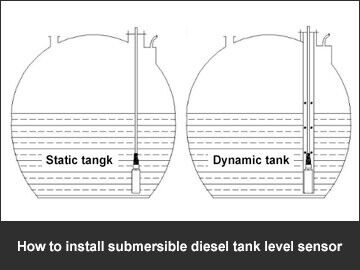

When using submersible diesel tank level sensor, the first thing to do is to install it. This is a key step. How do we operate it?

1.Static diesel level measurement

Directly put the fuel tank level sensor into the oil tank, protect the cable with the explosion-proof flexible hose that meets the requirements to minimize the risk of cutting and abrasion. At the opening of the container, use the mounting accessories and flanges provided by our company to fix the cable (junction box).

2.Dynamic diesel level measurement

When using submersible fuel level transmitter to measure the level of flowing or agitated liquid, the cable must be protected by an explosion-proof flexible hose that meets the requirements to reduce the risk of cutting and abrasion. The probe should be fixed with a PVC sleeve or steel pipe. (Prevent the probe from swinging, then affect the measurement accuracy) At the same time, make several small holes in the pipe wall at different heights on the opposite side of the fuel flow direction, so that the liquid flows into the pipe.

3. Notes when measuring

The installation direction of the submersible liquid level transmitter is vertical, and it should be away from the liquid inlet and outlet and the agitator. Deposits and sludge often accumulate at the bottom of diesel storage tanks, so a certain height is reserved to ensure that process connections do not get blocked after long time using.

The submersible diesel tank level sensor is cost-effective, provides excellent liquid compatibility, and has no reflection or foam problems. As long as the installation is completed, the tank data can be easily read in the control room. Through data analyzing and managing we can improve profitability of petrol stations.