Which Conductive Level Sensor Can Meet Our Requirements?

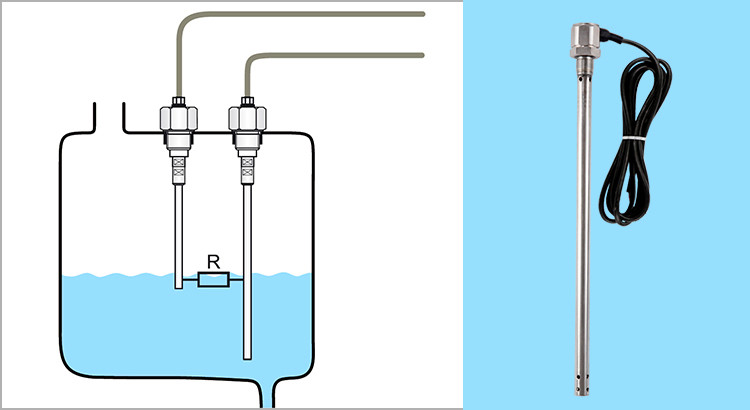

It is always a difficult problem for us to choose suitable conductive level sensor. For chemical plants, it is not easy to measure the medium of acid, base and salt in chemical tank. At the early stage of sensor development, most sensor manufacturers did not pay attention to this problem, which led to the conductive level sensor did not receive attention. At the same time, it does not give a real "answer" to the measurement of conductive liquid level.

Due to the increasing demand for measurement of various acid base aqueous solutions, the emergence of multipurpose capacitance level sensor provides an effective solution for conducting liquid level measurement. It is based on the capacitance change to the liquid level measurement, so the standard definition of the capacitance liquid level meter is capacitance is determined by the area of the two plates and the characteristics of the medium (dielectric constant).

Thus, it can be seen that the relationship between the conductive level sensor and the medium is that when measuring the conductive liquid, the infiltration area between the conductive liquid and the measuring electrode changes with the liquid level, which is equivalent to the area change of the capacitor plate, leading to the capacitance change. When measuring non-conductive liquid, the area of two electrode plates of capacitance is constant, the change of liquid level is equivalent to the change of dielectric constant of capacitor intermediate medium, the dielectric constant between two plates is converted from that determined by gas phase to that determined by liquid phase, and the change of dielectric constant leads to the change of capacitance.

It turns out that conductive level sensor is multipurpose capacitance level sensor, but over time, it is not only used for acid base water solution measurement of small tannks, but also more suitable for the level monitoring of truck tank.