What causes erosion of electromagnetic flow meter?

In 2018, a DCS operator in a chemical plant suddenly found out that the electromagnetic flow meter of the hydrochloric acid absorption device had jumped to zero, and its meter body had hydrochloric acid leakage. To prevent safety accidents caused by the leakage, the factory immediately stopped production. Since the device was put into operation in 2015, in order to ensure the concentration of hydrochloric acid at the pump outlet where a path of 36% hydrochloric acid was led back to the film absorber, and an electromagnetic flow meter was installed on the return pipe for flow detection.

After careful on-site inspection, it was found that the electromagnetic flow meter body was corroded and damaged, and about 1Kg of hydrochloric acid leaked. Hydrochloric acid is poisonous, corrosive, and volatile. Inhaling gaseous hydrochloric acid will seriously damage the human respiratory tract. If it continues to leak in large quantities, it will cause production accidents, pollute the environment, and even cause casualties. The on-site process staff contacted the instrumentation personnel urgently to solve the problems quickly. After replacing the meter head within 1h, the production was able to run normally.

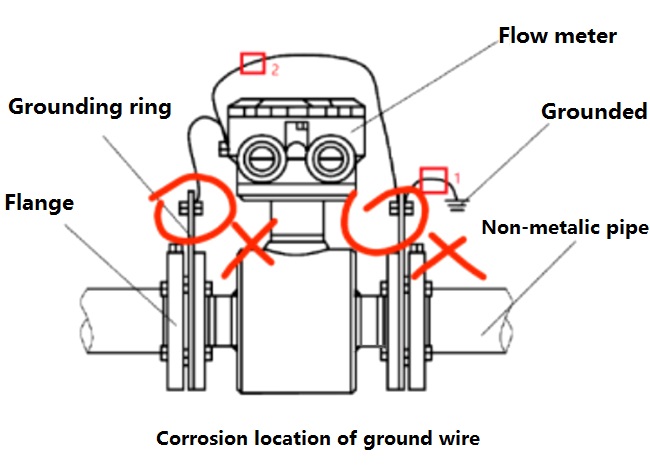

After 3 months, the same failure happened. This time, the instrument personnel and the manufacturer's engineer checked and analyzed the cause of the failure. After dismantling the flow meter, it was found that the inner lining was not damaged. After opening the meter, it was found that hydrochloric acid leaked from the four electrode connections, and the inside was severely corroded. The coil is completely damaged. Excluding the possibility of the external environment corroding the instrument coil, the cable at the connection of the grounding ring was found corroded, and the grounding resistance was infinite.

It turns out that acid gas leaks occasionally in the area of hydrochloric acid absorption unit, which leads to corrosion. The grounding wire at the connection of the grounding ring is corroded, and the grounding resistance is large, resulting in a potential difference between the fluid medium and the electrode, resulting in electrode surface effects and electrode corrosion, causing medium leaks and corrosion of coils.

What is a grounding ring? What should be noticed during use? Let me tell you.

1.When the fluid cuts the magnetic force line and sends out the flow signal, the fluid itself is used as the zero potential. A positive potential is generated on one electrode, and a negative potential is generated on the other, which are constantly alternately switched (when using low-frequency rectangular wave excitation). The grounding ring is used to ensure the fluid is at zero potential.

2.Its second function is to eliminate current interference and complex electromagnetic environment interference in the pipeline to ensure accurate measurement.

Therefore, we should pay attention to the correct use, installation, and maintenance of electromagnetic flow meter system to avoid unnecessary failures.