The importance of ultrasonic liquid level measurement

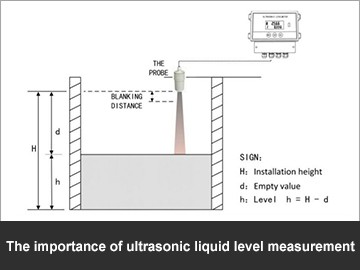

Ultrasonic liquid level measurement is the most important for modern industrial measurement. Although the submersible level sensor has a price advantage, but in most people's minds, ultrasonic liquid level measurement can meet the current measurement needs. However, it also has limitations in blind areas, beam angles, and measurement environments. Unexpectedly, the larger the measurement range, the more the blind areas it measures will increase, resulting in lower measurement accuracy.

As I mentioned above, ultrasonic liquid level measurement has advantages and disadvantages. Its advantage is that it can not only provide various liquid level measurement, but also monitor liquid level changes in real time. Based on Internet technology, it can be widely used in chemical, marine, food industry and harsh industrial environments. In addition, ultrasonic penetration and non-contact measurement methods are also popular with most people. In fact, it also has its shortcomings, mainly because it cannot be used for liquid level measurement of dust and bubbles, because such substances cannot transmit sound waves, so the sensor cannot collect information on the medium. Secondly, if the ultrasonic level sensor is used to measure the liquid level with a large measuring range, the measurement accuracy will be affected. If the precision deviation is too large, there is no substantial measurement significance.

Ultrasonic liquid level measurement will develop along with the development of the industry, and it may continue to provide more effective solutions for level measurement in the near future.