Installation Notices of Turbine Flow Meters

Let's learn about a flow measuring device called a turbine flow meter. It can be used to measure both liquids and gases, and very common in water treatment, petroleum, chemical, metallurgy, city gas pipeline network and so on.

Lean how to correctly install the turbine flow meters, we will benefit from this.

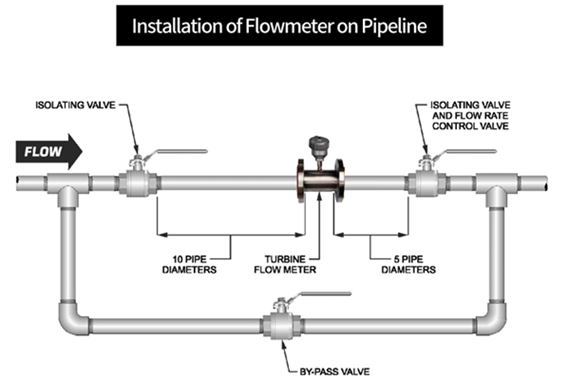

In order to ensure measurement accuracy, install turbine flow meters horizontally on a horizontal pipe, and the direction of the arrow indicated on the flow meter should be consistent with the liquid flow direction. If it must be installed vertically, the liquid should flow upwards from the bottom to ensure that the body of the flow sensor is filled with liquid.

2. In order to eliminate the influence of back flow, uneven flow velocity distribution and swirl flow, a rectifier can be installed upstream. At this time, the straight pipe length of the upstream portion of the flow sensor may be 10D.

3. When the measured liquid contains solid impurities, a filter should be installed upstream of the flow sensor. The mesh number of the filter is 20-60 mesh (3-9 mesh/cm2). Generally, the smaller the diameter of the flow sensor, the larger it is.