How to Choose Flow Meters for Different Applications

A flow meter is defined as a device that can be used for measuring the linear and nonlinear, volumetric and mass flow rate of gases or liquids. Correct selection of a flow meter is very important for the accurate measurement of the flow.

Different flow meters should be used under the different working conditions. If the flow meter is not properly selected at the beginning, it will even lead to the inability to measure the quantity and cause damage to the instrument. Therefore, it is necessary to have a correct understanding of how to choose a suitable flow meter for different applications. In order to ensure the best use of the flow meter on the production site, the selection of the flow meter in general, must be determined according to the medium to be measured.

Common working conditions can be referred to as follows:

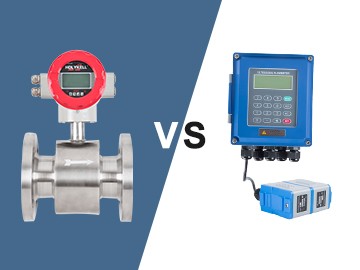

1. For turbid liquids such as sewage and pulp, we generally select ultrasonic flow meter and electromagnetic flow meter. However, when choosing an electromagnetic flow meter, it should be considered that the liquid does not contain bubbles.

2. For oils and diesel, we generally select mass flow meter, rotar flow meter, target flow meter, turbine flow meter and so on.

3. For the medium with large concentration and large solid particles, such as mortar and electro-powder slurry, we generally select electromagnetic flow meter.

4. For the medium with large flow of tap water, electromagnetic flow meter and ultrasonic flow meter. vortex flow meters, orifice flow meters are options.

5. For gases, ultrasonic gas flow meter, vortex/turbine flow meter can be used.

6. For the liquid medium with bubbles, ultrasonic flow meter can be used.

7. Pure water, demineralized water and other media with low conductivity, the options are ultrasonic flow meter.

8. For strong corrosive media such as acid and lye, electromagnetic flow meter lined with acid and alkali resistance and clamp-on ultrasonic flow meter are used.