Why does non contact ultrasonic liquid level sensor has blind spot?

The non-contact ultrasonic liquid level sensor is sure to have a sound blind spot. The quality of the ultrasonic sensors produced by the different sensor manufacturers is different. Choosing a high-quality continuous ultrasonic level sensor is the only way to improve the high efficiency of measurement, so let's take a look at why the non-contact ultrasonic level sensor has a blind spot.

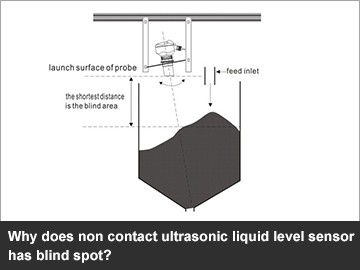

As we all know, the so-called blind spot is caused by the physical characteristics of the ultrasonic wave, because the ultrasonic probe is not able to detect the reflected echo normally for a small distance from the outer surface. This small distance is called the blind spot of non-contact ultrasonic ultrasonic liquid level sensor. The reflected wave cannot be detected normally within this small distance. This is because the non contact ultrasonic level sensor cannot detect the reflected echo at the same time when transmitting the ultrasonic pulse. Moreover, since the transmitted ultrasonic pulse has a certain time width, and the sensor has residual vibration after the ultrasonic wave is emitted, the ultrasonic liquid level meter cannot detect the reflected echo. Therefore, the blind spot of the ultrasonic liquid level sensor is different according to the range, and the blind zone is different. If the range is small, the blind zone is small and the range is large, and the blind zone is large. But usually it is between 30cm-50cm. Therefore, it is usually necessary to think about entering the time zone of the non contact ultrasonic level sensing of the device. In special occasions, the blind spot is required to be small. This time can be considered as a small blind spot ultrasonic level sensor, and the dead zone is usually only 4-6cm. However, its range is small, as long as 0.6m. In the category of many liquid level measurement, because of the space constraints, the constraints of the device conditions, the ultrasonic liquid level sensor with a small blind spot is required. Therefore, when the highest level measured is entered into the blind spot, the appearance will not be detected correctly and an error will occur. If necessary, the level gauge can be raised. In addition, for the application of the liquid level, the requirements for the blind zone are generally not high in the field of detecting the water level, but the requirements for the range are relatively high, whereas for some applications such as water tanks, there is a requirement for the blind spot.

This is the reason for the blind spot in the non-contact ultrasonic liquid level sensor, and it is also a technical error that cannot be avoided by the current technology. However, from a personal point of view, in the next few years, there will be a perfect solution for wireless level measurement.