Working Principle of Non-Intrusive Ultrasonic Liquid Level Gauge

Non-Intrusive Ultrasonic Liquid Sensor represents a significant leap forward in the field of industrial measurement, offering a safe, simple, non-intrusive and accurate solution for a wide range of applications especially in oil and gas measurement

Product Overview:

Our ultrasonic liquid level meter HU-TM operates on the principle of sonar distance measurement, allowing for the non-invasive measurement of liquid levels from the exterior of a container. This cutting-edge technology is designed to provide precise readings without the need for intrusive installations, making it ideal for use in environments where traditional contact-based level meters pose a risk or are otherwise impractical.

How It Works:

The meter consists of three main components: a measurement probe, a calibration probe, and a transmitter The probes are mounted externally, utilizing ultrasonic signals that reflect off the inner wall and the liquid-gas interface to calculate the liquid height. The transmitter, mounted on a post adjacent to the container, processes the signals from the measurement probe and converts them into a 4-20mA standard signal for integration with control systems.

Advantages:

Non-Intrusive Measurement: Our liquid level meter offers non-contact measurement, eliminating the risk of sparks or static that could lead to explosions in volatile environments.

Easy Installation: With no need for container penetration, installation is straightforward and cost-effective, making it an ideal choice for retrofitting existing systems.

Wide Range of Applications: Suitable for use in high-temperature, high-pressure, sealed, and hazardous environments, a variety of liquids, including flammable, explosive, toxic, and corrosive substances.

High Measurement Precision: Accuracy up to 1‰with an extremely low blind zone, ensuring accurate monitoring at all times.

Temperature Compensation Technology: Our advanced temperature compensation technology ensures consistent accuracy across varying temperatures.

Easy Calibration: Our unique pipeline calibration technique makes calibration a breeze, saving you time and effort.

Cost-Effective: The simple installation and calibration processes significantly reduce operational costs, making it an economical choice for long-term use.

Applications:

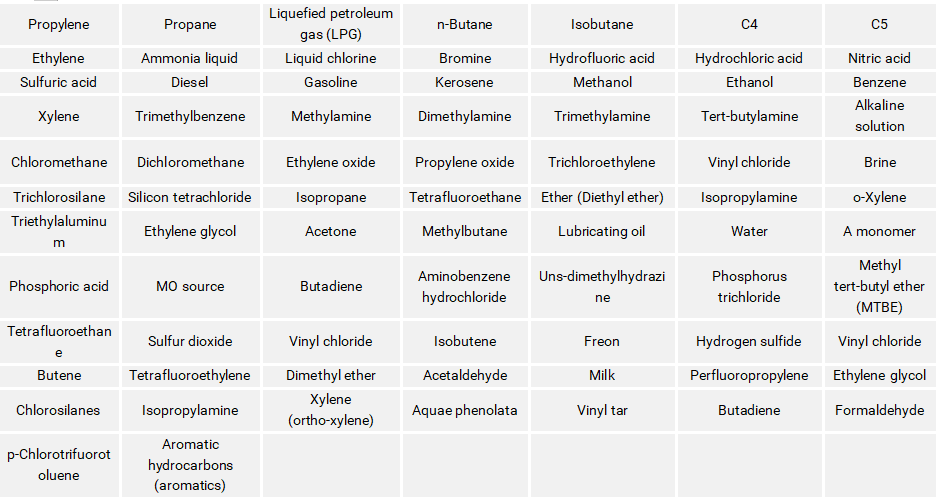

This table lists the main medium that can be measured by this device we’ve known.

For more technical data, contact us.