Understanding Tri-Rotameter: Working Principle, Applications, Advantages, and Disadvantages

Introduction

Tri-rotameters, also a type of positive displacement flowmeter and a variable area flow meter, are essential instruments in industrial and laboratory settings for measuring the flow rate of various liquids. Let’s explore the working principles, applications, advantages, and disadvantages today.

Working Principle of Tri-Rotameters

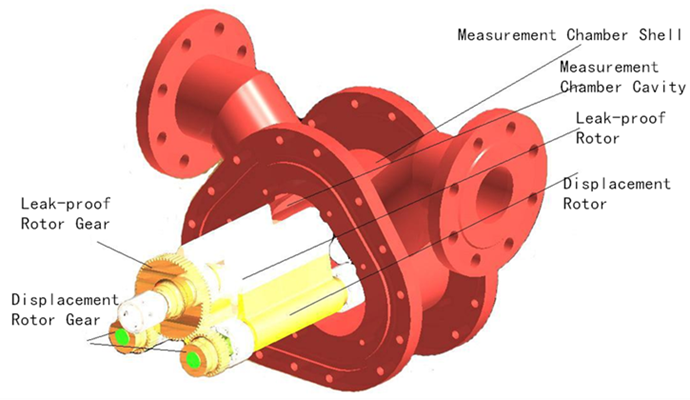

The measuring chamber of the triple-rotor flowmeter consists of a cylindrical inner chamber and three synchronously rotating rotors. These three rotors are housed inside the cylindrical rotor chamber. The gear of the leak rotor is mounted at the end of the leak rotor, and the gear of the displacement rotor is mounted at the end of the displacement rotor. This gear rotation structure ensures that the three rotors rotate synchronously. The number of teeth on the gear of the leak rotor is twice the number of teeth on the gear of each displacement rotor, so the speed of the leak rotor is half the speed of each displacement rotor.

When the fluid flows into the measuring chamber, the three rotors rotate synchronously, dividing the fluid into three parts. As the rotors rotate, the fluid in the measuring chamber moves simultaneously until it is discharged (as shown in the diagram). Since the volume of the measuring chamber is known, each rotation of the rotor discharges the same volume of fluid. By measuring the number of rotations of the leak rotor, the flow rate of the fluid through the measuring chamber can be accurately measured. The rotation of the leak rotor is transmitted to the counter for counting and outputs a standard pulse signal through the gears on its shaft and other transmission shafts.

Advantages

1.Wide Application:

Holykell ratometer can measure various types of media, including petroleum products, for example, crude oil, asphalt, fuel oil, lubricating oil, aviation fuel); industrial chemicals and products, for example, LPG, chemical processing fluids, and paints and coatings; construction materials, like cement mixtures; consumer products, like glue, ink, toothpaste, cosmetics; beverages and food; medicines, and more.

2.Various materials for the body and rotor:

The materials include steel, aluminum, copper, stainless steel, cast iron and more. Users can choose different materials for different applications.

3.Durable

With low mechanical friction, it has a long service life.

4.Strong adaptability

It adapts to changes in viscosity and offers consistent and accurate flow measurement. Thus, it’s widely used for metering in the transfer and trade settlement of various crude oil and refined oil products.

5.Various outputs

The rotameters can be connected to an explosion-proof pulse transmitter or a 4-20mA transmitter for remote measurement, enabling automated control.

Disadvantages

Precise calibration required.

Tri-Rotameter Applications Chemical Processing Pharmaceutical Industry Environmental Monitoring Water Treatment Biotechnology Petrochemical Industry Food and Beverage Industry

Contact us for more information about rotameters.