Use Notices of Coriolis Mass Flow Meters

Coriolis mass flow meter is a new technology but has a lot of advantages, though its price is higher than other flow meters. For example, it can measure mass directly rather than volume, thus it is a preferred choice in trade settlement. Here are some notices when using them.

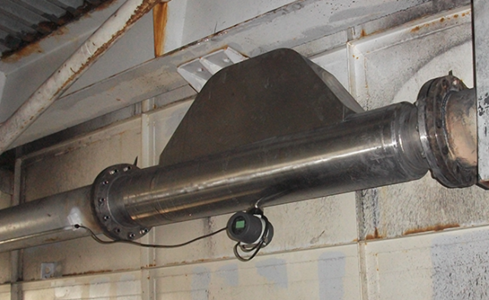

Coriolis mass flow meters measure the mass flow of liquids such as water, acids, corrosive liquids, chemicals, gases, and steam. The measurement is not affected by changes in fluid density. When using it to measure gas and steam flow, note the flow rate tends to be low (accuracy is decreased) in the flow range. In addition, in gas and steam applications, large pressure drop may occur in the flow meter and its associated piping, thus this flow meter is suitable for liquids that is hygienic, of low temperature, relatively clean, or corrosive and for gases and steam. in pipes less than 6~12 inches.

Coriolis mass flow meters can be made of different materials. For example, the measuring pipes can be made of stainless steel and HC alloy. HC alloy material is suitable for measuring some dirty liquids and/or abrasive liquids. Stainless steel is more suitable for sanitary applications. In addition, due to its relative insensitivity to density, Coriolis mass flow meters can be used in applications when we do not know well the physical properties of the fluid.