Method for Calibrating the Float Water Level Transmitter

Method for Calibrating the Float Water Level Transmitter

Float water level transmitters are essential instruments used in various industries to measure the liquid level in tanks, reservoirs, and other storage vessels. These devices use a float mechanism to detect changes in the liquid level and convert them into an electrical signal, providing accurate level readings. However, to ensure that the float level transmitter continues to operate correctly over time, periodic calibration is necessary. Calibration ensures the device’s accuracy and consistency, preventing errors that could lead to operational inefficiencies or system failures.

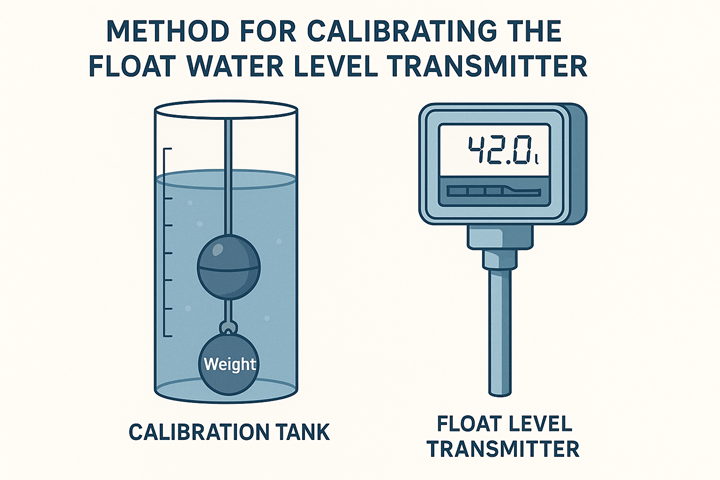

There are several calibration methods for the float water level transmitter, including hanging weight calibration and water-based calibration, each with its specific applications and advantages.

1. Hanging Weight Calibration: A Standard Approach

The most commonly used calibration method for float water level transmitters is the hanging weight calibration method. This technique involves using a known standard weight to simulate the force exerted by the float on the liquid. The basic principle behind the method is that the liquid level is directly related to the torque exerted on the float, and by applying a precise weight, the system can be calibrated to measure the correct liquid level at any given time.

To perform the hanging weight calibration, the float level transmitter is positioned in the same configuration it would have during normal operation. A standard weight, which corresponds to a known liquid level, is hung from the float. The transmitter then measures the resulting force or torque, and adjustments are made to calibrate the zero point (empty tank reading) and the full scale (maximum liquid level). This ensures that the transmitter’s readings are linear and accurate across the entire measurement range.

One of the advantages of this method is its high precision. By calibrating the transmitter over its full range, this technique ensures the accuracy of both the zero and full-scale points, as well as the linearity in between. As a result, this method is ideal for periodic performance checks, factory calibration, or when the float water level transmitter is newly installed or repaired.

2. Water Calibration Method: A Field-Friendly Option

In contrast to the precise but sometimes complex hanging weight calibration, the water calibration method is often used for field adjustments, fault repair, and general maintenance. This method is more convenient for on-site calibration and involves using clean tap water to simulate the liquid being measured. It is especially useful for calibrating external float water level transmitters, where removing or disassembling the equipment would be time-consuming or unnecessary.

To perform the water calibration, the float water level transmitter is submerged in a container filled with clean tap water. The sensor is set to measure the density of water, which is the most commonly available liquid for calibration. The parameters of the transmitter are then adjusted to reflect the density of water, ensuring that the liquid level readings correspond accurately to the water level in the container.

This method is widely used for quick field calibration, making it ideal for situations where the transmitter needs to be recalibrated on-site, such as during routine maintenance, after a fault repair, or in remote locations. The water calibration method is also effective for ensuring that the float water level transmitter provides accurate readings over a range of operational conditions. However, there is a limit to this calibration method: the measurement range obtained cannot exceed the transmitter’s maximum tolerance, so it’s essential to verify that the system is capable of handling the expected liquid levels.

3. Choosing the Right Calibration Method

While both hanging weight and water calibration methods have their applications, it is important to choose the appropriate technique based on the specific needs of the installation. For instance:

-

Hanging weight calibration is best suited for factory calibration, periodic checks, or situations where high precision is required. It ensures the float level transmitter operates within its full measurement range and is particularly useful for troubleshooting issues related to accuracy.

-

Water calibration is more practical for quick, field-based adjustments, especially in remote locations or when disassembling equipment is impractical. It is not as precise as hanging weight calibration but provides an efficient way to ensure the transmitter operates accurately in everyday situations.

4. Regular Calibration: Ensuring Long-Term Accuracy

Regardless of the calibration method used, it is essential to perform regular calibration to ensure the float water level transmitter continues to provide accurate readings over time. External factors such as temperature fluctuations, mechanical wear, or changes in the composition of the liquid being measured can affect the transmitter’s accuracy. Regular calibration helps identify and correct these issues, preventing costly errors and ensuring smooth operations in industries that rely on precise level measurements.

Additionally, when faults are detected or repairs are made, recalibrating the system is crucial to restore the transmitter’s accuracy and prevent future problems. Calibration should be performed according to the manufacturer’s guidelines or based on industry best practices.

Conclusion

Calibrating float water level transmitters is essential for maintaining their accuracy and reliability. Both hanging weight and water calibration methods offer distinct advantages, with hanging weight calibration providing high precision for factory and performance tests, and water calibration offering a more field-friendly option for on-site adjustments. Regular calibration ensures that these critical measurement instruments continue to function correctly, contributing to the efficiency and safety of various industrial processes.