Wireless Tank Level Sensors Used in Spanish Refinery

Customer

One privately owned refinery located in Spain.

Challenge

This refinery produces oil products including diesel, straight-run naphtha, fuel oil, crude oil, and asphalt. These materials arrive via tanker ships and are transported through a dual-pipeline system to either the refinery or a storage hub.

With over 200,000 m³ of total tank capacity distributed across more than 40 tanks—including both floating roof and fixed roof types—the site had relied on a hydrostatic tank gauging (HTG) system for many years.

While HTG provided acceptable mass measurements, volume readings were often inaccurate due to temperature drift. It used dual pressure transmitters to indirectly estimate levels, but they lacked stability and accuracy.

Additional issues included:

- Frequent inspection and maintenance

- Need for heating lines and insulation

- Manufacturer no longer supported the system

- Expanding to new tanks required complex cabling and significant installation effort

Solution: Embracing a Wireless Future

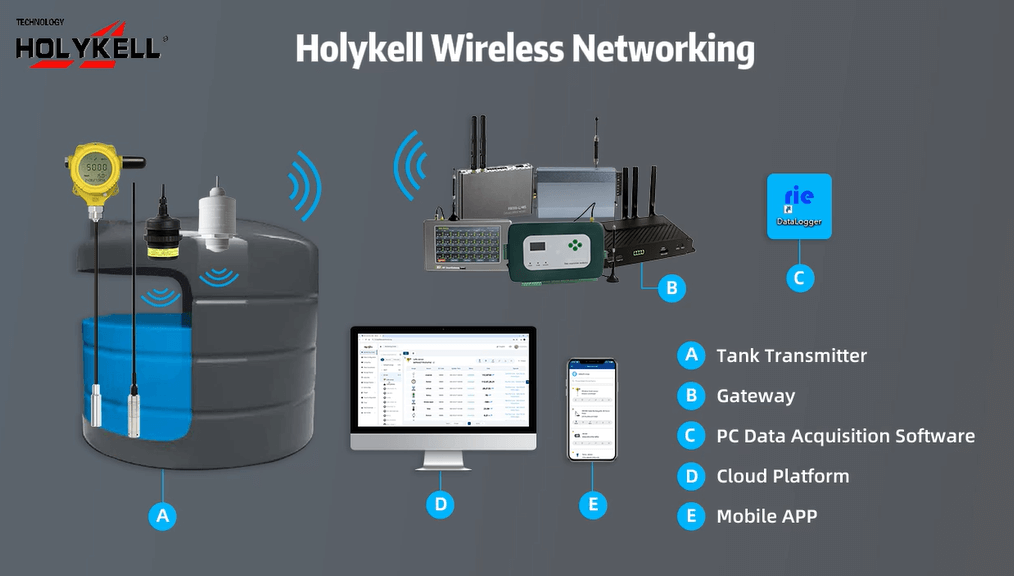

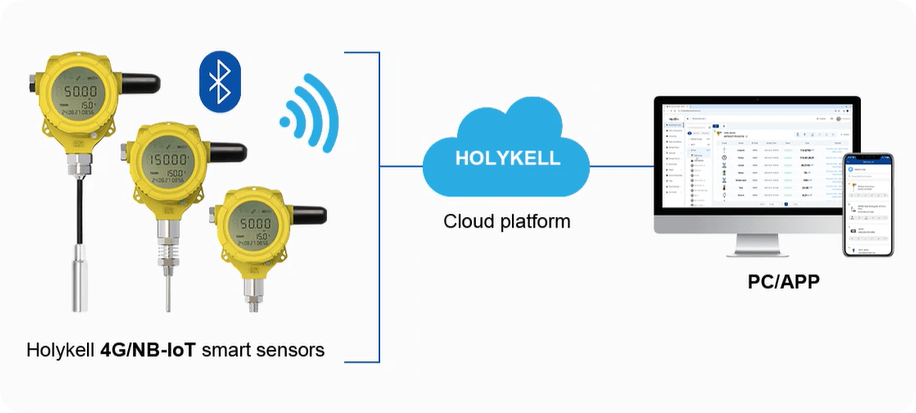

In 2024, the refinery’s engineering team looked for a scalable, accurate, and low-maintenance solution. That’s when they turned to Holykell’s smart wireless level sensor system.

The initial deployment covered nine tanks, each equipped with a wireless level sensor communicating via Modbus TCP/IP.

This marked a fundamental shift. Instead of laying cables or modifying the existing HTG system, the team installed all wireless transmitters in just 2 days—with no disruption to production and no junction box modifications.

The Results

- Immediate improvement in level accuracy and signal stability

- Direct measurement unaffected by pressure or thermal drift

- Remote data access from any location, at any time

- No recalibration or field service needed since installation

- The refinery now plans to upgrade more tanks as part of a phased expansion

Why Go Wireless? Key Benefits

- Higher Accuracy: Real-time, drift-free level readings

- Faster Installation: No cabling or complex setup—just a few days to deploy

- Maintenance-Free: Long-term performance without recalibration

- Easy Scalability: Add more tanks and instruments anytime

- Network-Wide Visibility: Unified monitoring across all devices

Lessons for Other Facilities

Many refineries and tank farms still rely on traditional wired systems due to concerns about costs or risks. However, this project shows that:

- Upgrading doesn’t mean replacing your entire infrastructure

- Wireless tech is suitable for large, complex facilities—not just remote sites

- A small investment can bring major long-term operational and financial benefits

About Holykell

Holykell is a global leader in industrial measurement solutions. We offer sensors for pressure, level, flow, and temperature, including advanced wireless products for oil & gas, chemical, water, and environmental applications. Our commitment to reliability and innovation helps operators make smarter, data-driven decisions.

Ready to Upgrade?

If you’re planning to expand your tank farm or modernize your level monitoring system, it’s time to consider a wireless solution.

Contact HOLYKELL today to learn more about how our wireless products can improve your operations.