Understand Impact of Dielectric Constant on Radar Level Meters

Introduction

In industrial applications, radar level meters are widely used for accurate, non-contact liquid level measurement. These devices offer high precision even in challenging environments, including extreme temperatures, pressures, and complex chemical compositions. However, one critical factor that influences the performance of radar level transmitters is the dielectric constant (DK) of the material being measured. The dielectric constant plays a pivotal role in the reflection of radar waves, directly affecting measurement accuracy.

This article explores the relationship between dielectric constant and radar level meter performance, providing valuable insights into how it impacts measurements in different industries, and offering best practices for optimizing sensor accuracy.

What is Dielectric Constant?

The dielectric constant (DK), also referred to as relative permittivity, is a material’s ability to store electrical energy in an electric field. It is a unitless number that represents how a substance influences an electric field. Materials with lower dielectric constants are good electrical insulators, while those with higher values are more conductive to electric fields.

How Does Dielectric Constant Affect Radar Level Measurement?

Radar level meters work by emitting electromagnetic waves toward the target material. When the signal encounters a boundary, such as a liquid surface, part of the signal is reflected back to the sensor. The amount of reflected signal is proportional to the dielectric constant of the medium.

High Dielectric Constant: Materials with higher dielectric constants, like water (DK > 80), reflect radar signals more strongly, making them easier for the radar sensor to detect.

Low Dielectric Constant: Materials with low dielectric constants, such as hydrocarbons (DK < 3), tend to reflect less radar energy, resulting in weaker signals and potential inaccuracies.

For example, vacuum has a dielectric constant of 1.0, metal conductors have an infinite dielectric constant. Low dielectric materials, such as hydrocarbons, have low values, making them poor reflectors of electromagnetic signals.

In radar level measurement, materials with higher dielectric constants reflect radar signals more effectively, leading to better measurement accuracy. Conversely, materials with low dielectric constants can weaken or scatter the radar signal, making it harder to obtain accurate measurements.

The percentage of the transmitted signal that is reflected back to the radar sensor is directly related to the material’s dielectric constant. If the dielectric constant is 8, this means that 8% of the transmitted energy is reflected back to the transmitter. Basically, a higher dielectric constant provides a stronger return signal, which is easier to measure.

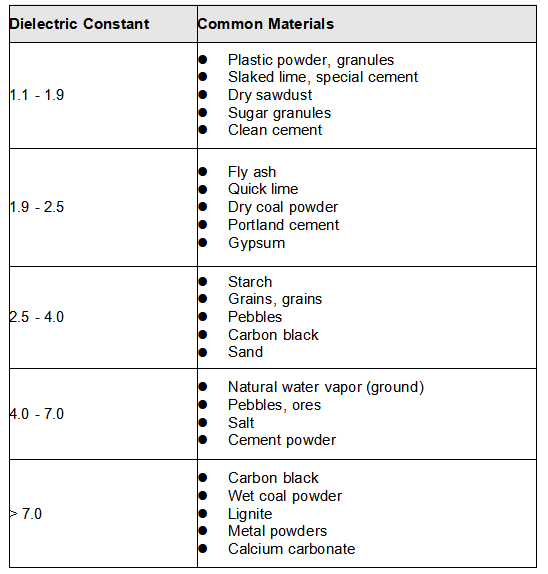

The above are the DK of common materials. Click here to download the Dielectric Constant Table for Various Materials.

Impact of Dielectric Constant on Specific Radar Applications

Water and Wastewater Treatment

Water, which has a high dielectric constant, is one of the easiest materials to measure using radar level meters. However, in water treatment plants, sludge or suspended solids (which have a lower dielectric constant) can pose challenges. To maintain accuracy in these cases, multi-frequency radar sensors or advanced signal processing algorithms are often employed to differentiate between the liquid surface and the solids.

Oil and Gas Industry

In oil and gas applications, substances such as crude oil or refined products have much lower dielectric constants compared to water. This makes them more difficult to measure with radar level meters. As a solution, radar sensors designed for low-dielectric liquids, with features like higher sensitivity and multi-echo technology, can help ensure accurate measurements even in these conditions.

Chemical Processing

Chemicals like acids, solvents, or other non-polar liquids can also have varying dielectric constants depending on concentration and composition. Radar sensors used in these environments must be carefully calibrated to account for changes in dielectric constant. Custom calibration profiles or dual-technology sensors are often employed in chemical processing facilities to provide more consistent results.

Using the wrong dielectric constant in radar level measurement can lead to significant measurement errors. This is especially critical in interface measurements, where precise detection of liquid layers is necessary.

For example, if the dielectric constant of the top liquid is incorrectly entered, the radar sensor may inaccurately calculate the interface between two liquids, leading to substantial errors. The error is calculated as follows:

Error = Physical thickness /the square root of DK1 – Physical thickness/the square root of the DK2

For instance, assuming a physical thickness of 20 inches (51 cm) and a change in dielectric constant from 2 to 4:

Error = 20 /√2– 20 /√4) = 4.14 inches (11 cm)

Interface Measurement Guidelines for Radar Sensors

The dielectric constant of the upper layer must be lower than that of the lower layer.

There must be at least a 6-point difference in dielectric constants between the two liquids for reliable interface measurement.

The dielectric constant of the upper layer must be known (it may need to be determined on-site).

Factors That Influence Dielectric Constant

Temperature

Temperature can affect the dielectric constant of materials. As temperature increases, the material’s molecular structure may expand, reducing its ability to store electrical potential, thereby decreasing the dielectric constant. For example, in hydrocarbons, the dielectric constant typically changes by 0.0013% to 0.05% per degree Celsius.

Moisture Content

The presence of water significantly increases the dielectric constant of materials. Dry materials, like sand or plastic, have much lower dielectric constants compared to wet materials. In some radar applications, moisture content must be accounted for to ensure accurate readings.

Material Type

Materials with high air content typically have lower dielectric constants, whereas materials with high water content will have higher dielectric constants. For instance, dry coal has a dielectric constant of 2.5, while wet coal could have a value closer to 7.

Best Practices for Optimizing Radar Level Meter Performance

Understand the material’s dielectric properties: Before choosing a radar level meter, make sure to fully understand the dielectric constant of the material being measured.

Choose the right sensor technology: For materials with low dielectric constants, select radar sensors with higher sensitivity and multi-frequency capability to improve signal detection.

Regular calibration: Ensure that radar sensors are regularly calibrated to compensate for any changes in material composition, temperature, or environmental conditions.

Consider environmental factors: Always factor in environmental conditions such as temperature, pressure, and vapor presence that may affect radar performance.

At Holykell, we offer advanced radar level meters designed to provide high accuracy, even in applications involving low-dielectric materials. Contact us today to learn more about our solutions for your specific measurement needs.