Radar Level Sensors: Types, Advantages, Limitations and Applications

Radar level sensors are commonly used tools used to measure liquid levels and convert them into electrical signals for integration with other instrumentation. By emitting and receiving high-frequency radio waves (microwaves), these devices accurately determine the distance to the liquid surface, making them popular in sectors like oil and gas, chemical processing, solids measurement, and water management.

There are two primary types of radar liquid level sensors: through air radar (TAR) and guided wave radar (GWR).

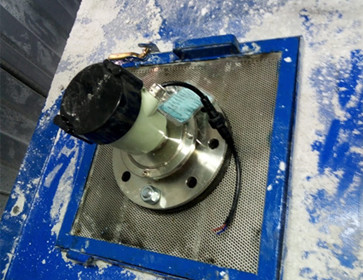

Through Air Radar (TAR) Level Sensor

Through Air Radar(TAR) level sensors are non-contact devices that use radio waves (microwaves) to measure the distance to the liquid's surface.

Advantages of Through Air Radar (TAR) Level Sensor

One of the significant advantages of TAR sensors is their ability to work well in environments with vapors, foam, and dust, which may cause interference with other types of sensors. Additionally, they offer excellent accuracy and reliability, making them ideal for critical liquid level measurements. Different types of antennas are provided to different applications. Since there are no moving parts, maintenance is very low.

However, the accuracy of TAR sensors can be affected by the dielectric constant of the material being measured. Low dielectric materials, like some hydrocarbons, may result in less precise measurements.

Guided Wave Radar (GWR) Level Sensor

Guided Wave Radar (GWR) level sensors use a probe to guide the radar signal along the liquid's surface, thus they are contacting radars.

The primary advantage of GWR sensors is their immunity to changing process conditions, such as temperature, pressure, and vapor presence. They can handle high-pressure applications and are less affected by foam or vapor. Moreover, GWR sensors can penetrate through non-conductive coatings on the probe, allowing measurements in vessels with a build-up of deposits.

However, when using these contact radars, echoes are formed when material adheres to the probe or there is something on the antenna, incorrect measurements are obtained. Thus cleaning is required.

Applications

Both TAR and GWR level sensors can measure almost all liquids and many solids. They can nearly handle all the applications which other liquid level sensors can do, including corrosive and non-corrosive substances, making them versatile for various industrial applications:

Oil and gas

Chemical processing

Water and wastewater management

Food and beverage

Pharmaceuticals

Power generation

……

Related Posts

What's the difference between Radar Level Transmitter and Ultrasonic Sensor?

What to Note for Using Radar Level Gauges