How to Choose the Right Wet Material: A Complete Guide

In industrial measurement, the choice of wet materials—the parts of a sensor or flow meter that come into direct contact with liquids—can determine the lifespan, performance, and reliability of your equipment. Whether you are monitoring aggressive chemicals, seawater, fuels, or food-grade liquids, material selection is critical, which will affect safety, maintenance costs, and long-term investment.

In this article, we will compare commonly used wet materials such as 316L stainless steel, Hastelloy C-276, Tantalum, Nickel, Titanium, and Monel. We will also explain how to choose the right material depending on your application.

Why Wet Material Selection Matters

Sensors and flow meters often operate in harsh environments where they are continuously exposed to liquids under pressure, temperature fluctuations, and chemical attack. A mismatch between the material and the medium can cause corrosion, stress cracking, or even catastrophic failure. By choosing the correct wet material, you can:

–Extend the service life of instruments

–Reduce maintenance and replacement costs

–Ensure measurement accuracy and stability

–Improve safety in chemical and hazardous environments

Overview of Common Wet Materials

The most common wet materials used include 316L Stainless Steel, Hastelloy C-276, Tantalum, Nickel, Titanium, and Monel.

316L Stainless Steel

316L stainless steel is the most widely used material for industrial sensors. It offers a balance of corrosion resistance, mechanical strength, and cost efficiency. It performs well in water, mild chemicals, and food industry applications. However, it is less resistant in highly acidic or chloride-rich environments, where pitting corrosion can occur.

Hastelloy C-276

Known for its outstanding resistance to both oxidizing and reducing environments, Hastelloy C-276 is often the first choice for chemical plants and flue-gas desulfurization systems. Its nickel-molybdenum-chromium composition, enhanced with tungsten, provides excellent defense against hydrochloric acid, wet chlorine gas, and hot contaminated media. The downside is its high cost and processing difficulty.

Tantalum

Tantalum offers almost complete immunity to strong acids, including hydrochloric and sulfuric acid at high concentrations. It is often referred to as a “super metal” for the chemical industry. While its corrosion resistance is unmatched, its price is significantly higher than most alternatives, and machining requires specialized processes.

Nickel

Pure nickel shows excellent resistance in caustic environments, such as concentrated sodium hydroxide. It also withstands neutral and alkaline solutions well. However, it is not recommended for strongly oxidizing acids like nitric acid. Its relatively lower cost compared to exotic alloys makes it a practical option in some alkali-related industries.

Titanium

Titanium combines light weight with excellent resistance to seawater, chloride ions, and many oxidizing media. It is widely used in desalination plants, marine applications, and aerospace. Titanium forms a stable passive oxide film, which protects it against corrosion even at elevated temperatures. The trade-off is higher cost than stainless steel and challenges in welding.

Monel

Monel is a nickel-copper alloy famous for its performance in hydrofluoric acid, seawater, and alkaline media. It offers strong mechanical properties and can handle both low and high temperatures. In marine engineering, Monel is used for propeller shafts and seawater valves. While less costly than Tantalum or Hastelloy, it is more expensive than stainless steel.

How to Select the Right Material

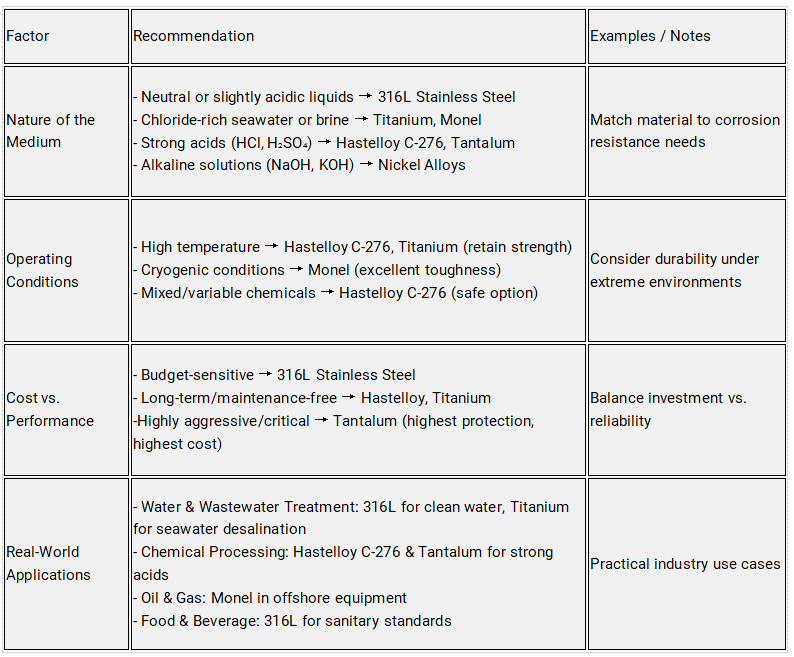

When deciding on wet materials for your sensors or flow meters, consider the following factors:

Conclusion

Selecting the right wet material for sensors and flow meters is a balance between performance requirements, operating conditions, and cost considerations. From cost-effective 316L stainless steel to premium options like Tantalum and Hastelloy C-276, each material has its own strengths and limitations. By understanding the properties of these materials, industries can make smarter choices that enhance durability, accuracy, and safety.

If you are unsure which wet material is best for your application, our team can provide tailored recommendations based on your process conditions.