How Differential Pressure Transducers Used in Filter Monitoring?

Differential pressure transducers are commonly used in industrial process systems, and they provide a great solution for those settings.

What is Differential Pressure Transducer?

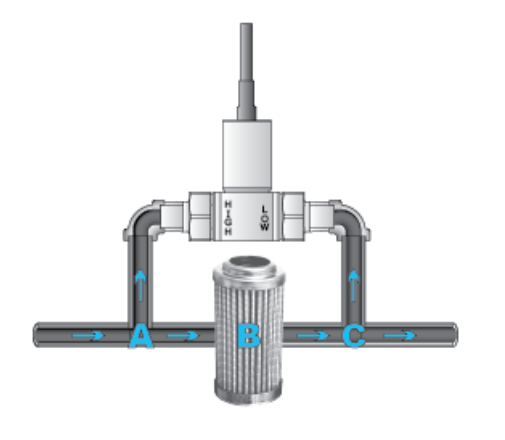

Differential pressure transducers are designed to measure and illustrate the difference between two points in a system. For example, if the pressure measured at point A is 90kpa and the pressure at point B is 60kpa, then the differential pressure by subtracting the low differential pressure from the high differential pressure is 30kPa.

Differential Pressure Transducers Used in Filter Monitoring?

Filter is an important part of an efficient operation in industrial process system, and differential pressure transducers are also vital as they can be used to detect if the filter is clogged. As shown in the figure, as the filter collects foreign materials, the pressure before the filter builds up. The more the filter gets clogged, the more the differential pressure increases. Once the differential pressure reaches a maximum value, the operator knows the filter should be changed.

Except being used in filtration, differential pressure transducers can be used in other fields and applications including but not limited to corrosive fluids and gas measurement systems, flow measurement and clean rooms, etc.

Related Posts

1. The working principle of differential pressure transmitter

2. Troubleshooting of Differential Pressure Transmitters

3. Maintenance Notices of Differential Pressure Transmitters

4. Differential Pressure Sensor for Leakage Detection

5. TOP 10 Differential Pressure Transmitter Manufacturers