How Coriolis Mass Flow Meter Used for Hydraulic Oil Measurement

A U.S.A manufacturer of construction machinery and equipment contacted us for a device for hydraulic oil flow monitoring, and a Coriolis mass flow meter has been recommended to him in terms of his application. The pipe diameter is DN100mm and the client has high requirements on accuracy and expects an explosion-proof certificate to ensure their safe production.

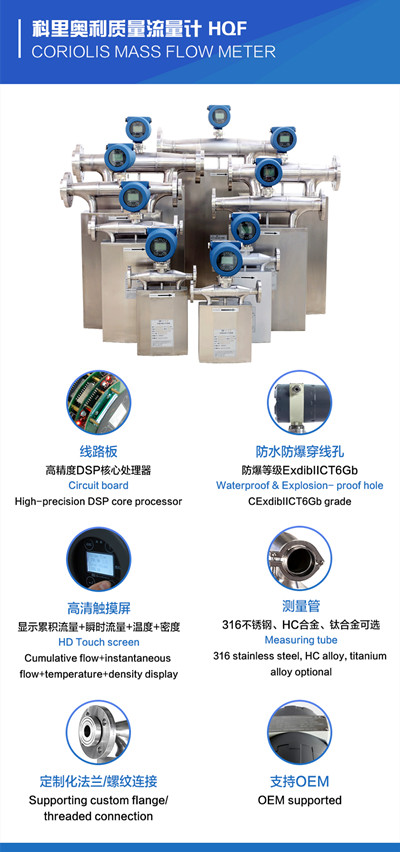

Product Profile

Holykell Coriolis mass flow meter HQF adopts the Coriolis force working principle and can measure flow, density and temperature parameters in multiple variables. The measurement accuracy is up to ±0.1%, the max medium temperature is +350°C (+662°F), and the min medium temperature is -200°C (-328°F). It has a DSP touch screen header that saves time for on-site operation, and a robust durable ultra-compact one-piece transmitter housing, IP67.

Measurement result

After on-site testing, our Coriolis mass flow meter HQF successfully started to operate in the project department, demonstrating the highest process safety of the mass flow meter, the characteristics of being unaffected by fluctuations and high measurement accuracy, and achieving customer satisfaction measurement results.

Application area

Coriolis Mass flow meters have a wide range of applications, such as process control, trade settlement, loading and unloading systems, and fluids that are difficult to measure, such as ultra-high temperature, ultra-high pressure, ultra-high viscosity fluids, and laboratory devices in universities and colleges.