Comparing Stainless Steel 304, 316 VS 316L

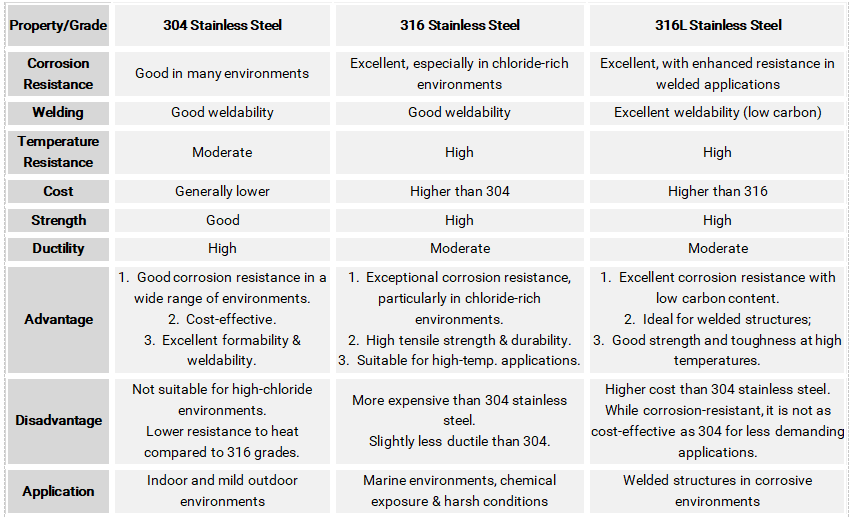

Stainless steel is a widely used material in various industries due to its durability, corrosion resistance, and aesthetic appeal. Among the many grades of stainless steel, 304, 316, and 316L are some of the most popular. Following we are comparing their differences, advantages and disadvantages, and their specific applications.

304 Stainless Steel

304 stainless steel is an austenitic grade that contains about 18% chromium and 8%~10.5% nickel. This combination gives it excellent corrosion resistance and good formability.

Known for its high tensile strength and resistance to oxidation, 304 is suitable for a wide range of applications. However, it is less resistant to chloride environments compared to 316 grades.

316 Stainless Steel

316 stainless steel includes 16-18% chromium, 10%~14% nickel, and 2%~3% molybdenum. The addition of molybdenum enhances its resistance to pitting and corrosion, especially in chloride environments.

316 is often referred to as marine-grade stainless steel due to its superior corrosion resistance, making it ideal for use in harsh environments. It also has excellent welding and fabrication properties.

316L Stainless Steel

316L is a low-carbon variant of 316 stainless steel. It has a similar composition but with a maximum carbon content of 0.03%.

The lower carbon content reduces the risk of carbide precipitation during welding, making 316L an excellent choice for welded applications. It retains the same corrosion resistance as 316 but offers improved performance in high-temperature environments.

Specific Applications

304 Stainless Steel is common in food and beverage Industry: Used in food processing equipment, kitchen appliances, and storage containers; architectural applications for building facades, railings, and decorative elements; chemical containers and pipelines where there is minimal exposure to chlorides.

316 Stainless Steel is frequently used in shipbuilding, boat fittings, and offshore platforms; pharmaceutical and medical equipment where hygiene is paramount; oil and gas industry, such as equipment and piping systems that operate in harsh environments.

316L Stainless Steel is used in applications requiring welded joints, such as pressure vessels and storage tanks, food and beverage such as sanitary equipment and food processing systems; chemical processing, such as reactors and storage tanks that handle corrosive substances.

314, 316 and 316L are also the common housing and sensor material for sensors, flow meters and other measuring instrument. When deciding these materials, we can select basically from below info:

How to Select Between 314, 316 and 316L for Sensors and Flowmeters?

We are Here For Help

Holykell, a sensor manufacturer from China, is specialized in the R&D and production of pressure, level and flow monitoring devices for over 20 years. Our broad portfolio of sensors and flow meters and readily available expertise enable you to optimize your processes and meet your performance goals.

Holykell experts are here to support you regarding the product selection and technical guidance. Contact us here NOW.