Choosing Between PVC, PUR, FEP, and PE Cables for Liquid Level Sensors

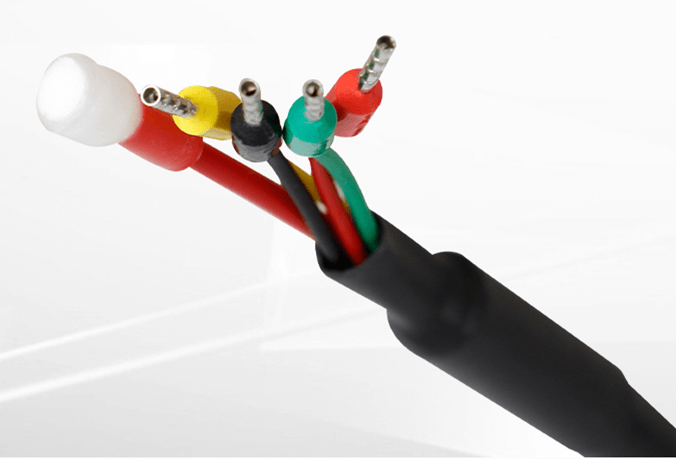

When specifying electrical connections for sensors, selecting the right cable type is crucial. The choice of cable jacket depends on various factors, including budget, application environment, and compatibility with liquids. Here, we’ll explore the properties of four common cable types—PVC, PUR, FEP, and PE—to help you make an informed decision for your application.

PVC (Polyvinyl Chloride) Cables

PVC cables are a popular choice due to their versatility and cost-effectiveness. They operate effectively in temperatures ranging from 0 to 105°C. One of the key advantages of PVC is its flexibility, making it easy to install in various environments. Additionally, PVC offers good chemical and abrasion resistance, which is essential when dealing with different liquid types.

PVC’s characteristics make it suitable for a range of applications. However, it’s important to note that while PVC is resistant to moisture and saltwater, it is not halogen-free, which can be a concern in some fire-sensitive environments. PVC cable is suitable for non-submersible measurements. It provides the best price-performance ratio, making it an attractive option for budget-conscious projects.

PUR (Polyurethane) Cables

PUR cables are designed to withstand more challenging environments than PVC cables. With an operating temperature range of -45 to 80 °C, PUR cables are particularly abrasion-resistant and highly flexible, even at low temperatures. They are also halogen-free and self-extinguishing, making them safer in case of fire.

With their ability to resist oils, oxidation, and ozone, PUR cables are ideal for environments where exposure to harsh chemicals is common. The use of PUR cables can significantly enhance the reliability and longevity of electrical connections in demanding applications.Typical applications for sensors include measuring seawater and diesel.

FEP (Fluorinated Ethylene Propylene) Cables

FEP cables take chemical resistance to another level, making them suitable for the most aggressive environments. Operating at temperatures between -45 and 80°C. FEP cables feature a combination of PUR and PTFE (Polytetrafluoroethylene) covers, providing exceptional resistance to all types of chemicals.

These cables are particularly valuable in applications where compatibility with aggressive liquids is paramount. Their ability to perform reliably in extreme conditions makes FEP cables a top choice for industries dealing with corrosive substances and high temperatures. While they may come at a higher cost than PVC or PUR, the durability and resistance of FEP cables can result in lower maintenance costs over time.

PE(Polyethylene) Cables

PE cables are designed for applications requiring flexibility and durability. They can operate in a broad temperature range of -45 to 80°C.

It can withstand external pressure and weight, and can resist corrosion from chemicals such as acids and alkalis. It also has good wear resistance, anti-aging, and flame retardancy. Typical applications for sensors include measurement of water.

Conclusion

By understanding the properties of PVC, PUR, FEP, and PE cables, you can make an informed choice that aligns with your project requirements, ensuring the longevity and performance of your sensors. Whether you’re working with industrial applications or sensitive environments, the right cable selection is essential for operational success.

For more technical guidance on cable jacket materials, contact us here.