A Comprehensive Guide to Radar Level Meters: Principles, Types, Applications, and FAQs

Radar level meters are essential instruments in industrial automation, offering accurate and versatile measurements for almost all the liquids and solids. This article collects the most frequently asked questions associated with radar level meters from our customers.

How Does A Radar Level Meter Work?

Radar level meters use electromagnetic waves to measure the distance between the instrument and the surface of a material. By analyzing the time taken for the radar pulse to return, the device calculates the level of the material with high precision.

Types of Radar Level Meters

1. Guided Wave Radar Sensors(contact type radar)

Guided wave radar (GWR) sensors use a probe to guide radar pulses directly to the medium, providing stable and reliable measurements.

Applications:

Suitable for tanks with foam, vapor, or turbulence.

Works well with liquids, slurries, and even solids in narrow or complex tanks.

Advantages:

Minimal interference from external conditions.

Reliable in low-dielectric or challenging media.

2. Pulsed Radar Level Sensors (Non-Contact)

Pulsed radar level sensors are non-contact devices that transmit electromagnetic waves through the air to measure the level.

Applications:

Commonly used in open tanks, reservoirs, or when contact with the medium is not feasible.

Works well for clean liquids, corrosive chemicals, and bulk solids.

Advantages:

Non-contact design reduces maintenance.

Extreme pressure and temperature conditions capable.

3. FMCW Radar Level Sensors (Non-Contact)

Frequency Modulated Continuous Wave (FMCW) radar sensors are advanced non-contact sensors that provide high-precision measurements. The higher the frequency, the more precise the measurement.

Applications:

Ideal for applications requiring high accuracy, such as small tanks or granular solids.

Food processing, pharmaceuticals, and precision chemical manufacturing.

Advantages:

Extremely precise measurements, even in narrow tanks or complex geometries.

Measurement unaffected by temperature, pressure or dust,

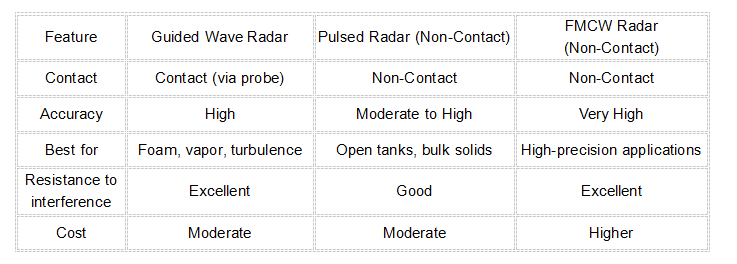

Comparison Table

FAQs

1.Is safe to use radar technology?

Yes. The reflected signal is less than 3% of the maximum amount of leakage allowed by a microwave oven. The intensity of radar waves is no greater than the continuous radio waves, waves generated by mobile phones, and other communication devices that surround us daily. Moreover, transmitters are generally placed inside metal tanks, which act as Faraday cages, isolating the radar waves within the tank.

2.How build-up on antenna affects measurement?

Dust or sticky substances can accumulate, weakening the signal. If the medium itself has a high dielectric constant, some fouling may not be a significant issue. However, if the medium has a low dielectric constant, fouling can become a problem. If a dual-tube or coaxial guided wave rod is used, fouling can cause bridging between the two tubes, which will generate false echoes, leading the transmitter to interpret the bridge as the actual liquid level. In cases with fouling, it is recommended to use a single-tube guided wave rod. Fouling can affect accuracy. The error caused by fouling depends on the type of guided wave rod, the dielectric constant, the thickness of the fouling, and the height of the fouling above the product surface. The maximum error can range from 1% to 10%. Regular cleaning or using self-cleaning antennas can help.

3.How dielectric constant of the medium affects measurement?

All radar devices emit electromagnetic energy. When the transmitted signal reaches a point where the dielectric constant changes, part of the signal is reflected back to the transmitter. In other words, typically at the surface of the medium, a portion of the signal is reflected back. The energy reflected back to the transmitter is proportional to the dielectric constant of the medium. The value of the dielectric constant represents the percentage of energy reflected. Therefore, if the dielectric constant is 8, it means 8% of the transmitted energy is reflected back to the transmitter. In conclusion, radar performance depends on the dielectric constant of the material being measured. Low dielectric materials may reflect weaker signals.The higher the dielectric constant, the stronger the return signal, making it easier to measure.

4.Can radar level meters work in tanks with agitation?

Yes, guided wave radar is particularly effective in such conditions as it provides stable readings despite turbulence.

5.Can radar sensors measure foam-covered liquids?

The effect of foam on radar measurement is difficult to predict. In some cases, foam may completely eliminate the signal, while in others, the signal may penetrate the foam and reach the transmitter. When evaluating foam impact, factors such as thickness, density, and dielectric constant should all be considered.

The operating frequency of the radar also affects foam measurement. Generally, lower frequencies are better at penetrating foam, while guided wave radar can also be a reliable choice.

6. Will two or more radar devices placed in the same container interfere with each other?

No, you can use more than one radar device in a single tank. The transmitters’ pulse signals are very fast, and the starting times of each transmitter are independent, so they do not interfere with each other.

If you use two or more guided wave radar devices, the effect of nearby objects on the guided wave rods is similar to their effect on other nearby metal objects. Therefore, a certain distance should be maintained between the guided wave rods.

7.Are radar level meters suitable for measuring solids?

Absolutely. High-frequency radar, like 80 GHz, is particularly effective for granular solids due to its narrow beam angle.

8. Can radar measure an emulsion layer?

Generally speaking, the emulsion layer is difficult to predict. When an emulsion layer is present, sometimes the measured interface is the top of the emulsion layer, other times it is the bottom, or sometimes it is somewhere in between. The results vary depending on the mixing of the fluids and the dielectric constant difference between the two liquids. In most cases, the measured interface is the top of the emulsion layer. A thin emulsion layer (< 2″ or 50 mm) may not be detected at all.

9.What maintenance do radar level meters require?

While radar level meters are generally low-maintenance, periodic inspections are recommended to clean antennas and check connections.

Conclusion

Radar level meters are versatile, reliable, and indispensable for industries requiring precise level measurement. Understanding their principles, types, and advantages can help you choose the right instrument for your application.

If you have more questions about radar level meters or need assistance in selecting the right product, feel free to contact us.