The applications of magnetostrictive level meter

Magnetostrictive level meters are widely used for measuring liquid levels in process containers because of their high precision and maintenance-free properties. In fact, when used in various types of water and oil tanks, most users are happy to use this high precision magnetostrictive level meter to complete the measurement. Although this type of level sensor does not have a price advantage, it covers all level measurements, including water, acid-base solutions, ammonia, and petroleum.

Magnetostrictive level meter can replace float liquid level sensor. Most float level sensors have the following problems: first, their output and output errors are due to gravity changes and torsional tube leakage, process media bonding on the torsional tube and converter. The magnetostrictive level meter can be inserted into the existing filter buoy or a new type of external float, which can solve the problem of insufficient accuracy of the float level sensor.

Magnetostrictive level meter can be used for interface measurement. And it is one of the best liquid level interface measurement and control technology. Magnetostrictive level meteres can provide two independent outputs, the interface and the overall level, and they can be applied to the state with the smallest specific gravity difference. Therefore, it can be used for oil-water interface measurements and other types of acid-base tanks, propane tanks, etc.

Magnetostrictive level meters can be used not only in industrial measurements but also in biopharmaceutical and food processing industries.

Related Posts

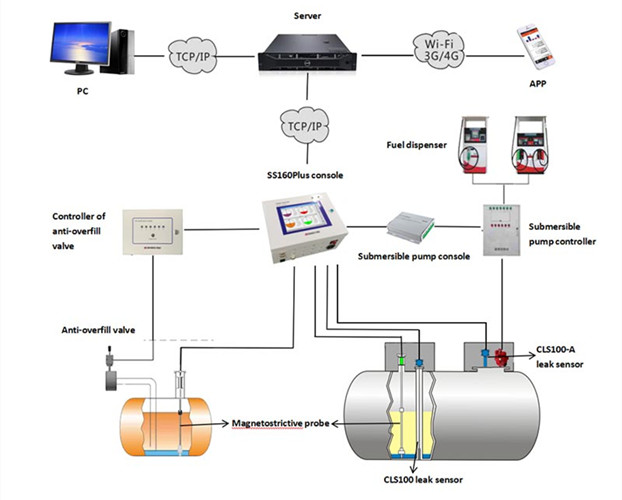

Magnetostrictive Level Transmitter for Gas Station